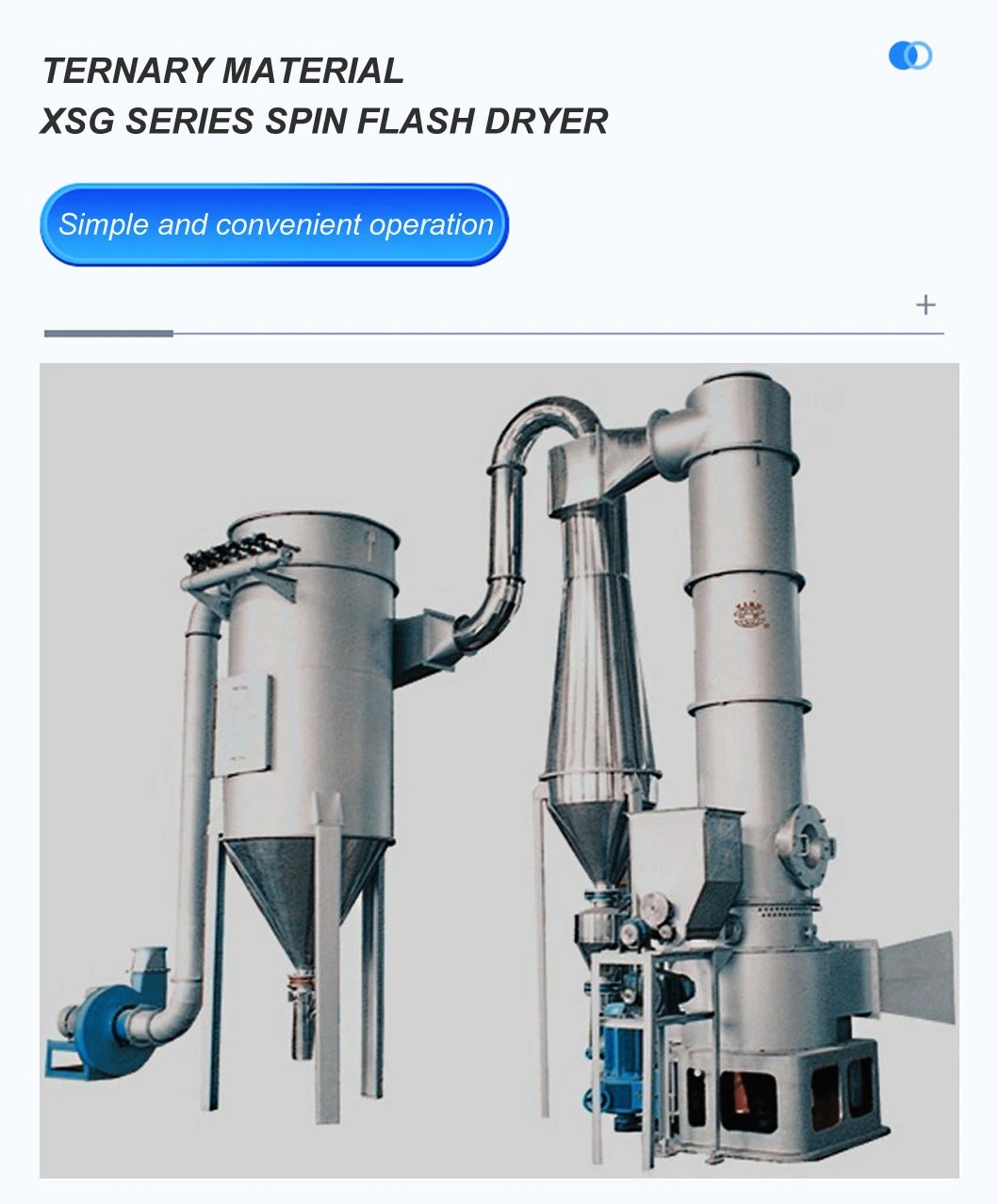

1600mm Barrel Diameter Xsg-16 Industrial Spin Flash Dryer

Basic Info

| Operational Method | Continuous |

| Produce Certificate | ISO9001&14001 |

| Energy Consumption | High Drying Intensity, Low Energy Consumption, and |

| Suit | Heat Sensitive Materials |

| Volume | Small Size, High Production Efficiency |

| Technology | Combination of Swirl, Fluidization, Jet and Crushi |

| Velocity | Instantaneous Drying |

| Environmental Protection | Negative Pressure or Micro Negative Pres |

| Laminated Material | PTFE |

| Transport Package | Wooden Case |

| Specification | XSG-200, XSG-300, XSG-800, XSG-1600, XSG-1650 |

| Trademark | YiBu |

| Origin | China |

| HS Code | 8419399090 |

| Production Capacity | 38 Sets/ Year |

Product Description

XSG Series Spin Flash Dryer Specially-designed For The Batter MaterialProduct Description

☆DescriptionsBase on the foreign advance equipment and technology , our company and the shenyang chemical industry research institute of the Ministry of Chemical Industry cooperated with each other to design and develop this series of equipment . It is used to dry paste material with viscosity , filter cake and heat sensitive material . We have lab - type of XSG - spin flash dryer in our company for customer test .☆PrincipleHeated air enters into the main tower of flash dryer tangentially from air inlet at bottom of main machine and forms high - speed air flow which cyclone alike , at the same time , to adjust the ring - gape of bottom according to the different material ' s property in order to have the proper air speed . Materials enter into drying tower directly through spiral feeder . With the striking and driving of high - speed air , the materials are separated fast and rotating in high speed . For the big agglomerations with high humidity , high - speed air flow can not make them into pieces and let them rotate in high speed . With the effect of gravity , the big agglomerations with high humidity fall gradually . When they reach the bottom of main machine , they are broken up forcibly and granulated , and then they go up reelingly along with high - speed air flow as to finish drying process . There are screeners set on the top of main machine and the final water content and fine of discharging can be controlled through adjusting screener and the speed of inlet air .

Structure and characteristics

☆Combination technology of the whirl , fluidization and broken grading .☆The equipment is very compact , small volume , high efficiency production with continuous operation , achieve : small machine with big production .☆Large intensity of drying , low energy consumption , high thermal efficiency .☆ The material stay time is short , product quality is good , it can be used for drying thermal sensitive material.☆Operation is under Micro pressure or negative pressure , good sealing , high efficiency and eliminate the pollution of the environment .

☆To install the arch - breaking stirring device at the parts close to the screw inside the wet material hopper , the stirring device speed is same to the one of the screw , in this way , the wet material can be delivered into the dryer continuously , uni - formally and quantificationally . At the same time , in view of the battery material filter cake has the characteristics of viscosity , we design double - helix for the conveying screw . The spiral slice staggered and cut into each other . So it is easy to destroy each other viscous material " axis " phenomenon , the double helix has self - cleaning function , and use the inverter to adjust the speed .☆Equipped the insulation layer with the inside of the conical section of the main tower as to avoid the heat inside the main machine transfer to shaft parts . For the shaft and bearing parts , we enforce the oil - cooling and lubricating system for them , not choose the tranditional grease to lubricate them .☆The pin flash drying is a kind of continuous fast fluidization drying , belongs moment - drying . The key parameter for the moisture away from the products is the temperature that can let the Air - solid leave away from the main drying machine .relatively speaking , the lower the final moisture requires , the higher the outlet air temperature the main drying tower has .

☆With the drying experiences , because the final moisture of the finished product should be controlled very low , the outlet temperature of the main drying tower should be at 100°ºC~160°ºC. For such high tail air , we can use plate heat exchanger to recycle them , and then take them as pre - heating system . in this way , we can achieve energy saving and emissions reduction .☆Due to the battery material particle size is very small , it is supper - fine powder , so the filter bag in the bag dust collector should coated with PTFE materials as to effective filtering micro powder . meanwhile ,The effect of material itself has hydrophobic , when using it , it can maximum limit to reduce water and other oily material adhesion on the surface of filter bag , and less dust adhesive to the surface of the filter bag . The cloth bag dust effect is good . At the same time , the filter area of the bag filter configured in the project enough bag , and the whole bag dedustor runs well with low resistance and high dust collection efficiency .

Product Parameters

Non-standard design is customer request

| spec | Barrel diameter(mm) | Main machine dimensions(mm) | Main machine power ( kw ) | air velocity ( m 3 /h ) | Water evaporation capacity ( Kg/h ) |

| XSG-2 | 200 | 250×2800 | 5-9 | 300-800 | 10-20 |

| XSG-3 | 300 | 400×3300 | 8-15 | 600-1500 | 20-50 |

| XSG-4 | 400 | 500×3500 | 10-17.5 | 1250-2500 | 25-70 |

| XSG-5 | 500 | 600×4000 | 12-24 | 1500-4000 | 30-100 |

| XSG-6 | 600 | 700×4200 | 20-29 | 2500-5000 | 40-200 |

| XSG-8 | 800 | 900×4600 | 24-35 | 3000-8000 | 60-600 |

| XSG-10 | 1000 | 1100×5000 | 40-62 | 5000-12500 | 100-1000 |

| XSG-12 | 1200 | 1300×5200 | 50-89 | 10000-20000 | 150-1300 |

| XSG-14 | 1400 | 1500×5400 | 60-105 | 14000-27000 | 200-1600 |

| XSG-16 | 1600 | 1700×6000 | 70-135 | 18700-36000 | 250-2000 |

Application

Company Profile

Certifications

Packaging & Shipping

FAQ

1. Are you a manufacturer , trading company or a third partyAnswer: We are professional manufacturer ,together with the trading business . we have started our production on 1970 based on the right of state .it became private company in 1995

2. Where is your factory located

Answer: Our company is located in Zhenglu Town,Tanning district ,Changzhou city ,Jiansu province,China .it is in the middle of Shanghai and Nanjing .

3. How can I go to your factory ?

Answer: You can fly to shanghai pudong or hong qiao international airport directly ,and then take the high speed train or bus to Changzhou station and then we can pick you up at changzhou station for our company . Our company is around 30~40km away from the changzhou station.If you are in China now , you can fly to Changzhou Benniu airport or Wuxi airport ,or take the train or bus to our city directly .We sincerely welcome to visit our company at any time.

4. What's your mini order ?

Answer: Our mini order is one set .

5. Is there any certificate of YIBU ?

Answer: Yes, we got ISO9001:2008 Quality Management System Certificate,ISO14001:2004 Environmental Management System Certificate, CE;SGS;TUV;GOST;UL;EAC also we got 60 item patent.

6. Is the machine easy to performance update?

Answer: YES. YIBU adopt the modularity design technology .YIBU can improve the dryer performance to extend the dryer's long time service. Our dryer is easy to disassemble, clean and maintenance.