Daily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making Machine

Basic Info

| Model NO. | JF-A |

| Certification | CE, RoHS |

| Application Area | Daily Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Frame Scraper |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Machine Material | SUS304&SUS316L |

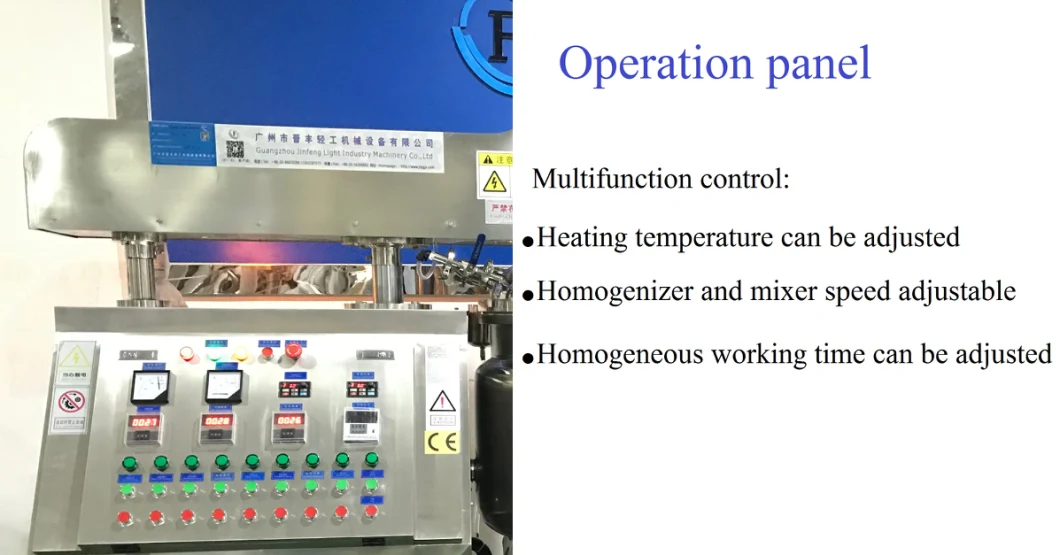

| Control | Button/ Touch Screen |

| Heating Method | Steam/Electricity |

| Range of Spindle Speed | 0-60 r.p.m |

| Thickness | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm etc. (Design Accordin |

| Jacket | Single Layer, Double Jacket, Three-Layer |

| Shape | Cylinder or Cone, Conical /Flat/Elliptical Bottom |

| Transport Package | Plywood Case Packing Suitable for Sea,Air Shipping |

| Specification | 50-5000L(customized is accepted) |

| Trademark | JINFENG |

| Origin | China |

| HS Code | 8474900000 |

| Production Capacity | 50-5000L(Customized Is Accepted) |

Product Description

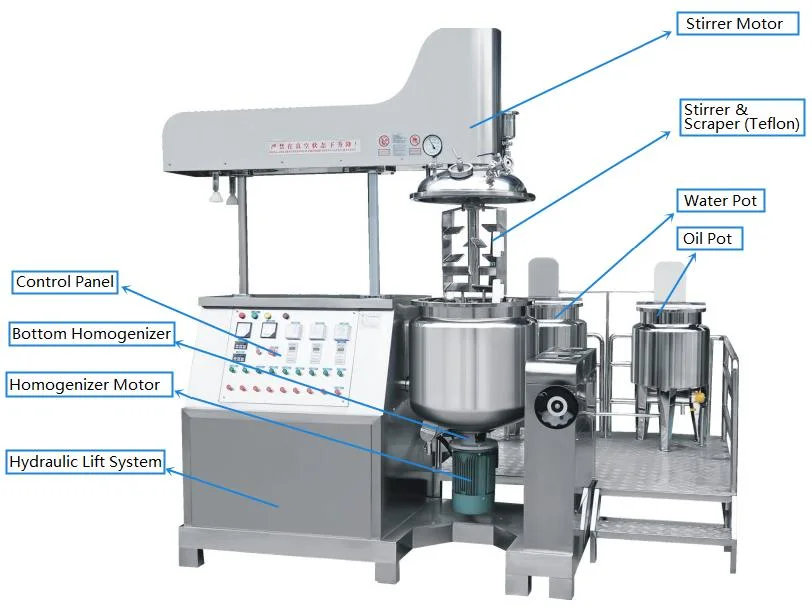

Daily Hand Cream Cosmetic Lotion Vacuum Homgoenizer Mixing Making MachineProduct Description

Feature

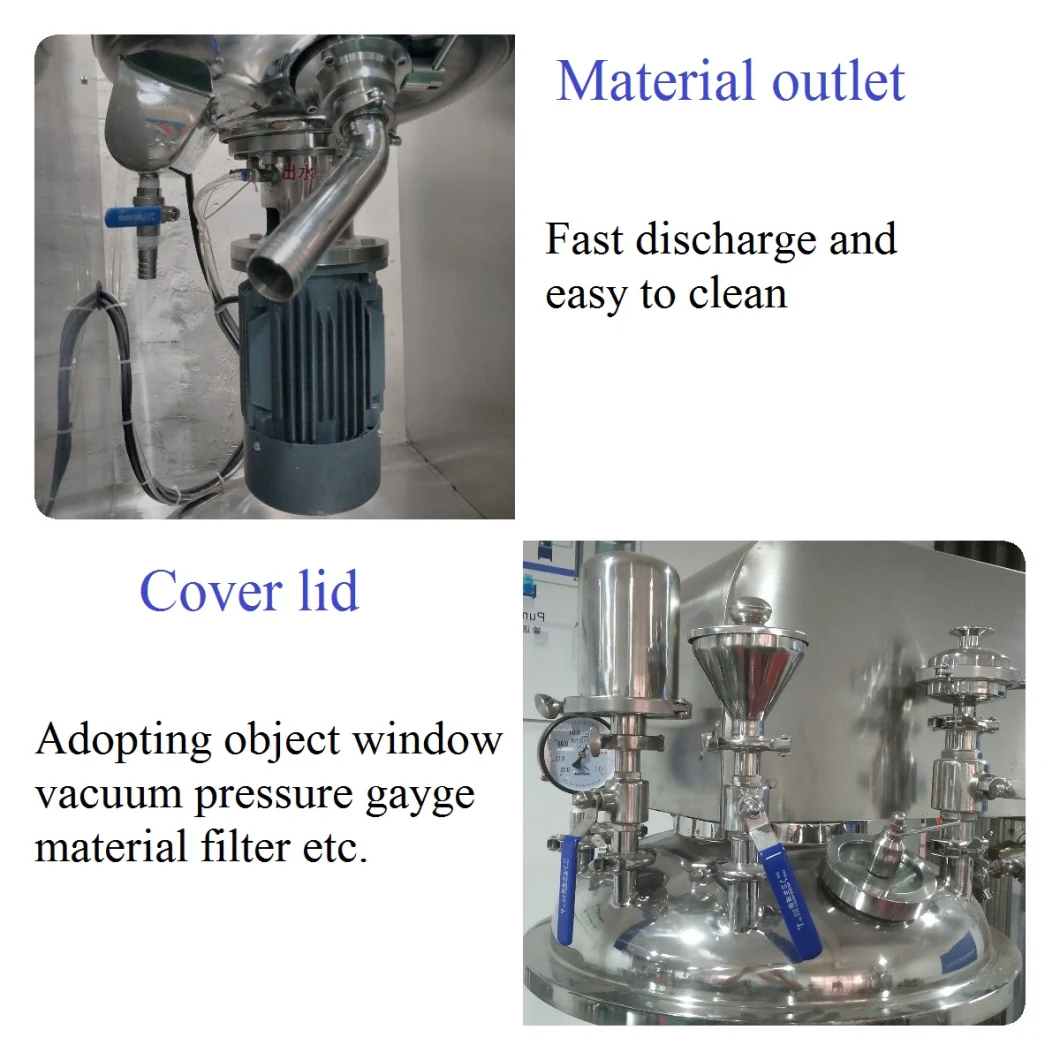

JF-A vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. Products through introducing advanced technology from abroad. The machine unit is composed of pretreating boiler, vacuum emulsifying and blending boiler , vacuum pump. Hydraulic system, dumping system , electric control system and work platform etc. The machine unit is featured by simple operation , stable performance, good homogenizing performance , high production efficiency , convenient cleaning , reasonable structure , small land area and high automatic degree etc.AdvantageThe unit adopts the upper coaxial three-heavy agitator, the hydraulic lifting and opening cover, the speed of the fast homogenizing agitator: 0-3500r/min (frequency conversion speed regulation), the slow speed scraping wall agitator speed: 0-63r/min (frequency conversion speed regulation) ), the homogenizer adopts a high-shear eddy-type emulsification mixer, and the slow-speed wall scraping and stirring automatically adheres to the bottom and wall of the pot. Vacuum suction is adopted, especially for powder materials to avoid dust flying. The whole process is carried out under vacuum conditions to prevent the material from generating air bubbles after high-speed stirring, which can meet the requirements of sanitation and sterility. The system is equipped with a CIP cleaning system, the contact part of the container and the material is made of SUS316L material, and the inner surface is mirror-polished 300EMSH (sanitary grade). In order to ensure the stability of the control part, the vacuum pump is made of German Nassim (formerly Siemens) products, and the buttons are made of well-known domestic products. Delixi products and frequency converters use Taiwan's Delta, and electrical control parts use well-known domestic brand products. This unit is manufactured in full compliance with GMP requirements, and is currently the most advanced and ideal production equipment for creams and creams in China.

Use

It is suitable for production of ointment and cream products in cosmetic and pharmaceutical plants .The emulsifying effect is more prominent for materials of high base viscosity and high solid content .

Product Parameters

| Model | Effective capacity(L) | Emulsifier | Agitator | Dimension(mm) | Total Power(KW) | ||||||

| KW | R/min | KW | R/min | (L) | (W) | (H) | Max Height | Electric heat | Steam heat | ||

| JF-A-20 | 20 | 0.75 | 0-3000 | 0.37 | 0-40 | 1800 | 1600 | 1850 | 2700 | 9 | 3 |

| JF-A-50 | 50 | 2.2 | 0-3000 | 0.37 | 0-40 | 2700 | 2000 | 2015 | 2700 | 25 | 5 |

| JF-A-100 | 100 | 3 | 0-3000 | 1.5 | 0-40 | 2920 | 2120 | 2200 | 3000 | 27 | 9 |

| JF-A-150 | 150 | 3 | 0-3000 | 1.5 | 0-40 | 3110 | 2120 | 2200 | 3100 | 27 | 9 |

| JF-A-200 | 200 | 4 | 0-3000 | 1.5 | 0-40 | 3150 | 2200 | 2550 | 3100 | 40 | 12 |

| JF-A-350 | 350 | 4 | 0-3000 | 2.2 | 0-40 | 3650 | 2650 | 2700 | 3600 | 50 | 16 |

| JF-A-500 | 500 | 5.5 | 0-3000 | 2.2 | 0-40 | 3970 | 2900 | 3150 | 3950 | 50 | 16 |

| JF-A-1000 | 1000 | 11 | 0-3000 | 4 | 0-40 | 3900 | 3400 | 3150 | 4550 | 100 | 30 |

| JF-A-2000 | 2000 | 15 | 0-3000 | 7.5 | 0-40 | 4850 | 4300 | 3600 | No rise and fall | 120 | 30 |

Detailed Photos

Packaging & Shipping

We will packs all of the machine and parts in the firm case that suitable for shipping.

Company Profile

FAQ

1. About Delivery termQ: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients. 2. About Lead timeQ: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on production schedule is in slack or peak season, and the complication of machines. 3. About Payment timeQ: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.4. About QualityQ: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment. Meanwhile,CE is available for customers' needs.5. About PackingQ: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.6. About CustomizedQ: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.