High Efficiency Biofuel Energy Tree Branches Granulator Flat Die Wood Pellet Mill

Basic Info

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | 1 Years |

| Pellet Mill Type | Ring Die |

| Application | Making Wood Pellets |

| Product Name | Pellet Mill |

| Pellet Formation Rate | Over 98% |

| Size of Wood Pellets | 4/6/8/10/12mm |

| Length of Wood Pellets | Adjustable Pellet Machine Suppliers |

| Materiall for Making Wood Pellets | Sawdust, Rice Husk, Hop.Wood Chips, Wood Shaving S |

| Spare Parts of Wood Pellet Machine | Ring Die and Roller |

| Colour | Client Requirement |

| Key Words | Pellet Mill |

| After-Sales Service Provided | 24 Hours Online Service |

| Transport Package | Wooden Box, Iron Frame |

| Specification | 1-4t/h |

| Trademark | zhangsheng |

| Origin | China |

| HS Code | 8465960000 |

| Production Capacity | 100 Set/Month |

Product Description

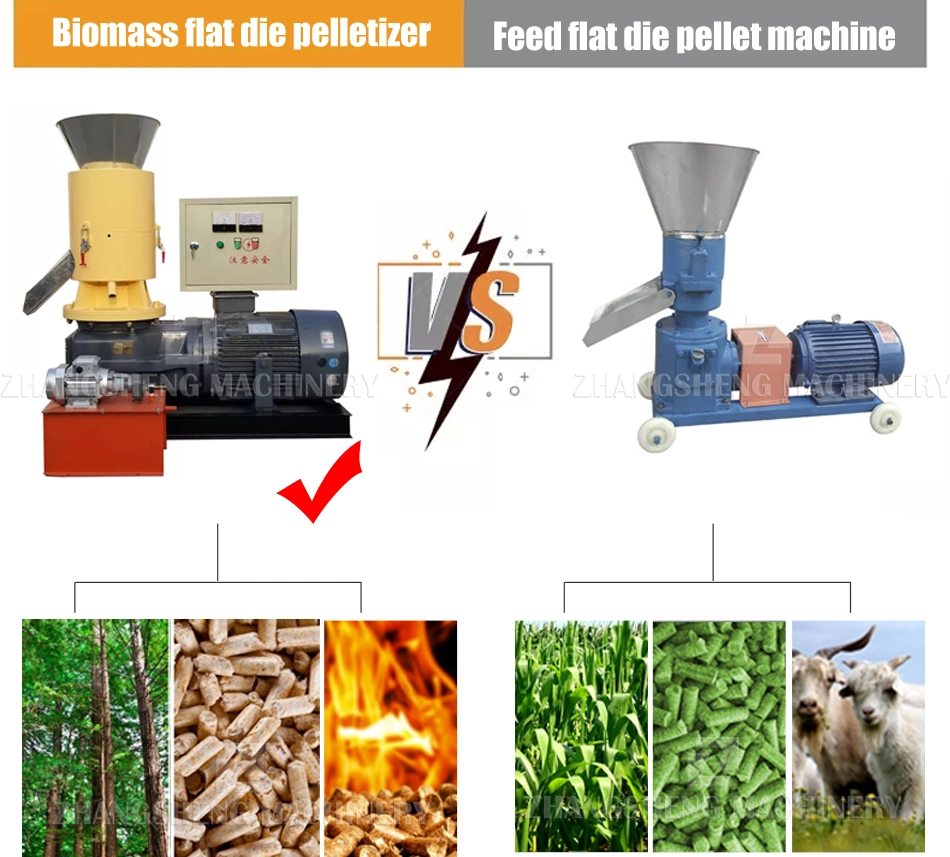

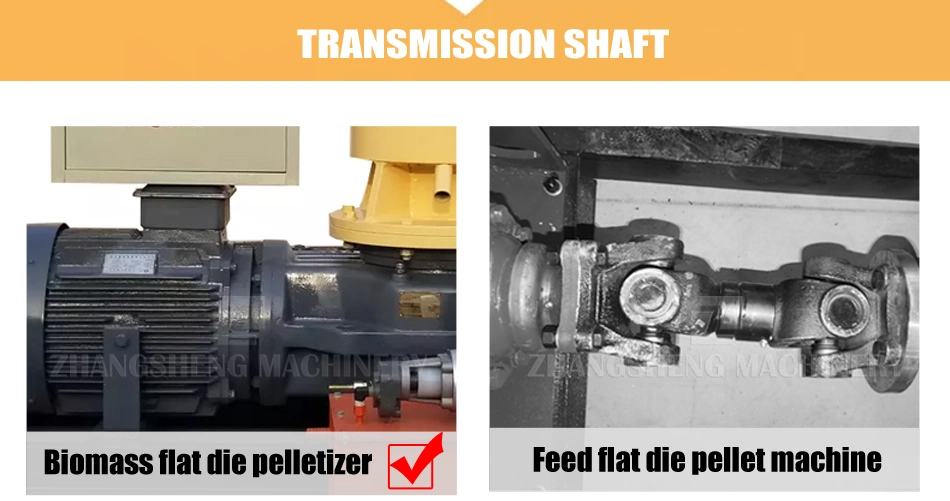

direct drive The casing of the reducer is made of high-strength cast steel, and the motor is directly connected to the hard-tooth surface reducer for smooth operation, greater extrusion force, and good biomass pellet forming effect. | universal joint drive The motor is used to connect the universal joint and the differential transmission, which has high noise, small extrusion force and poor particle forming effect. |

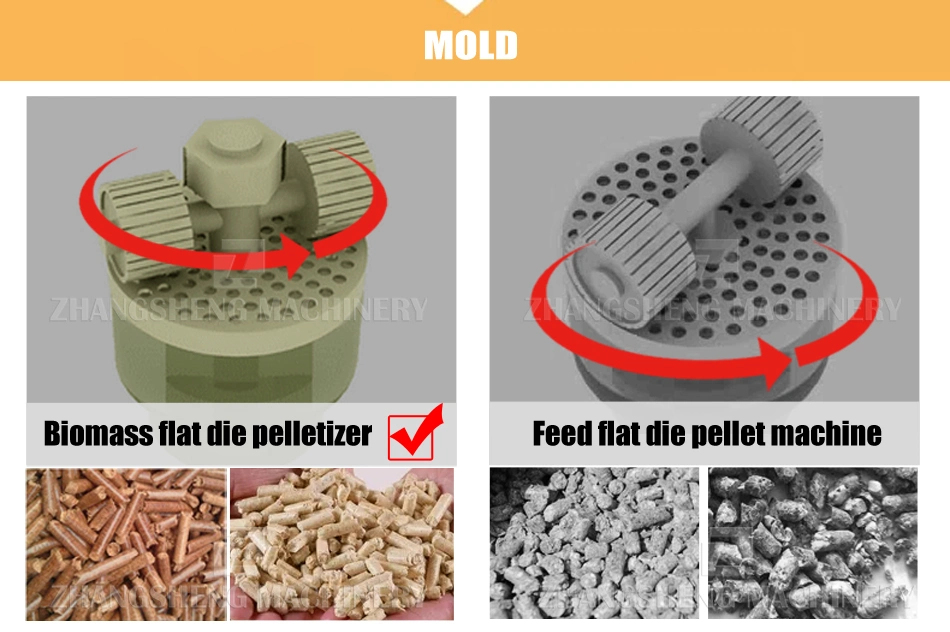

mold stationary The mold is static and the pressure roller rotates. The pressure roller adopts the groove width, large pressure, and good wear resistance. More suitable for making pellets from materials with low adhesion rate such as wood chips and straw. | mold rotates When the mold rotates and the pressing wheel is stationary, the extruded particles will be beaten twice with the mold, resulting in poor particle forming effect. |

Product Description

Fully automatic lubrication system, easier to use and maintain

The wood pellet machine has an automatic lubricating oil system, which can automatically lubricate the vertical shaft. If there is no automatic lubricating system, it needs to be manually refueled every four working hours. It is cumbersome to operate.Change the grinder to make different pellets at any time.

The compression molding of this model is diversified. biomass granules (4-Φ12mm) only need to change the molds. It is suitable for compression molding of different materials and achieves more benefits.The best material for abrasives and rollers, working long hours to make wood pellets

The wood has high hardness. The ordinary 42CrMo (42 chrome molybdenum) abrasive tools and pressure rollers are used, which wears very quickly. We all use super wear-resistant alloy steel 20CrMnTi (20 chrome manganese titanium), and the pressure rollers can be repaired 2-3 times. Repeated use, continuous use time increases by 60%, ideal for making wood pellets.Our high-efficiency pellet mills are suitable for a variety of biomass feedstocks Wood chips, branches, straw, bamboo chips, bagasse, peanut shells, alfalfa, rice husks, coconut shells, EFB palm fibers, etc. can be pressed into pellets.Product Parameters

| Model | Power(kw) | Yield(kg/h) | Dimension(m) | Weight(t) |

| ZS200 | 7.5 | 50-80 | 1*0.44*1 | 0.4 |

| ZS250 | 15 | 100-200 | 1.12*0.44*1.06 | 0.6 |

| ZS300 | 22 | 150-250 | 1.28*0.55*1.2 | 0.8 |

| ZS350 | 30-4 | 300-400 | 1.3*0.53*1.2 | 0.9 |

| ZS400 | 37-4 | 400-500 | 1.4*0.6*1.5 | 1.2 |

| ZS450a | 45-4 | 600-800 | 1.62*0.69*1.6 | 1.5 |

| ZS450b | 55-4 | 900-1000 | 1.7*0.69*1.6 | 1.6 |

| Note: Including electric control, oil pump | ||||

Packaging & Shipping

Packed in high quality metal frame, with board on the bottom for support and extra plastic wrap for protection.Ensure that the machine is delivered to you intact and without damage, and start production immediately.

Company Profile

Henan Zhangsheng Environmental Protection Equipment was established in 2005, and has passed ISO and CE certification. The products have been widely exported to more than 60 countries and have been well received by customers. As a professional supplier of wood pellet mills and whole plant project solutions, Zhang Sheng can always meet the needs of different customers. We understand the importance of quality and the importance of timely delivery. We know how to survive and thrive because we always focus on long-term development.FAQ

Here are some frequently asked questions from customers:Q1: Where is your factory? Can I visit?

Of course, you are welcome to visit our factory. It is in Zhengzhou City, Henan Province,China. We have more than 15 years of experience in the pellet manufacturing industry, and all common types of equipment are in stock and ready to ship.Q2: What is the use of biomass wood pellets? As a new source of energy, biomass pellets are mainly used for combustion to provide heat energy. It has the characteristics of high calorific value, low ash content and environmental friendliness.Q3: Which raw materials can be made into biomass pellets? The line can handle large quantities of raw materials, forestry wastes such as logs, branches, trunks, planks, roots and other types of wood. Wooden pallets, formwork, wooden frames and other construction waste. Agricultural wastes such as straw and forage.Q4: I know very little about pellet production line, how to choose the most suitable machine?do not worry. We have helped a lot of beginners. Just tell us your raw material, your capacity (t/h) and the size of the finalpellet product, we will choose the machine for you according to your specific situation.Q5: Our workers don't know how to operate the pellet mill, what should I do?Our engineers will guide the field workers how to install the machine and arrange the workshop layout. Our engineers will then test run the live production line and train your workers how to operate it.Q6: In which countries do you have projects? Products are exported to more than 40 countries such as the United States, Canada, Australia, Africa, Kenya, Tanzania, Algeria, Morocco, Sudan, Australia, Malaysia, and the Philippines.We have machines in many countries, if you have machines in your country, we can contact customers to arrange a visit for you.