Industrial Mineral Processing Rotary Drum Dryer for Gypsum, Sand, Coal, Cement, Slag, Slurry, Limestone, Ore Powder, Rotary Dryer Price

Basic Info

| Model NO. | DDSG |

| After-sales Service | Online Support, Field Installation |

| Warranty | One Year |

| Movement Way | Agitation |

| Atomization | Rotary Atomization |

| Flow | Cross Flow |

| Heating Mode | Transmission |

| Material Status | Powder, Bulk |

| Drying Medium | Superheated Steam, Effluent Gas |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Capacity | 300-2500t/D |

| Initial Moisture | 25±5% |

| Final Moisture | ≤12 |

| Total Power | 109-1200kw |

| Condition | New |

| Color | Customized |

| Certification | CE, ISO |

| Transport Package | Standard Package |

| Trademark | DONGDING |

| Origin | China |

| HS Code | 8419399090 |

| Production Capacity | 20 Sets Per Month |

Product Description

Industrial Rotary Dryer Introduction

Our mineral rotary dryer is special designed for drying various mineral raw materials. The external drying host adopts multi-layer heat preservation technology. According to the characteristics of mineral materials, special lifting and cleaning devices are set inside to prevent materials from sticking to the wall, fully realize mass and heat exchange. The mineral materials can be dried quickly with low cost. The drying time and temperature can be controlled in the whole process. Besides, the operation cost is greatly reduced, and the comprehensive economic benefit is improved.

Performance Features of Mineral Rotary Dryer

1. The inner part of the mineral rotary dryer is made of wear-resistant manganese plate, which is 3-4 times more wear-resistant than ordinary steel plate.

2. The initial moisture content of the material is 15%, and the final moisture content after drying is less than 0.5-1%, which can be used as slag powder of cement plant, dry and wet mortar production line, etc.

3. Adopt special heat preservation system, the thermal efficiency of the mineral rotary dryer is increased by more than 40% compared with the traditional dryer.

4. The fuel has wide applicability, and the low quality fuel coal can be used.

5. There is no air leakage phenomenon, and the sealing difficulty is completely solved.

6. The discharge temperature is less than 60 ºC, it can be directly fed into the warehouse without cooling.

7. The temperature of the outer drum is less than 60 ºC, the temperature of the exhaust gas is less than 120 ºC, and the service time of the bag of dust remover is more than 2 times longer.

Mineral Rotary Drum Dryer Application

The mineral rotary dryer is special designed for drying bentonite, clay, limestone, gold ore, iron ore, pyrite, river sand, copper ore and other materials. It is widely used in mineral processing, metallurgy, building materials, chemical industry and other industries.

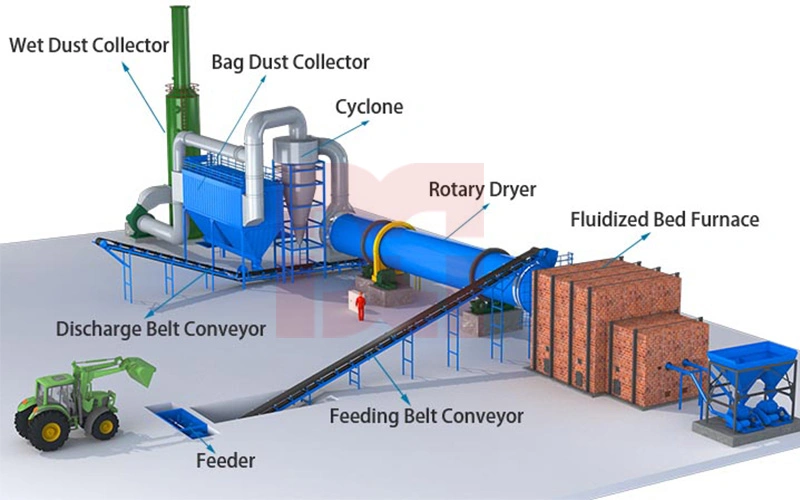

Working Principle of Mineral Rotary Drum Dryer

Mineral raw materials are delivered into the hopper by belt conveyor or bucket elevator, and then enter into drying system by feeding mechanism. The guide device installed in the rotary dryer will lifts the materials to the top and drops them. The materials are broken by the high-speed rotating blades in the dryer when falling down. It is repeated until move to the outlet. At the same time, the hot air generated by the high temperature heat source enters into the dryer to fully contact with the materials, so that the materials are dried quickly, and then discharged through the conveyor at the discharge end.

Product Parameters

| Specification | Capacity(T/D) | Initial Moisture(%) | Final Moisture(%) | Total Power(kw) | Floor Area(m2) |

| DDMG1918 | 300±10 | 25±5 | ≤12 | 109 | 7m*25m |

| DDMG2218 | 500±30 | 25±5 | ≤12 | 128 | 8m*30m |

| DDMG2520 | 700±30 | 25±5 | ≤12 | 240 | 8m*30m |

| DDMG2822 | 1000±30 | 25±5 | ≤12 | 400 | 8m*40m |

| DDMG3024 | 1200±30 | 25±5 | ≤12 | 480 | 12m*50m |

| DDMG3428 | 1500±30 | 25±5 | ≤12 | 600 | 12m*60m |

| DDMG3830 | 1800±30 | 25±5 | ≤12 | 800 | 16m*70m |

| DDMG4032 | 2000±30 | 25±5 | ≤12 | 1000 | 18m*70m |

| DDMG4238 | 2500±30 | 25±5 | ≤12 | 1200 | 20m*80m |

Packaging & Shipping

Working Site

Company Profile

Zhengzhou Dongding Machinery is a high-tech enterprise integrating R&D design, production installation, production management, sales, after-sales service and technical consultation, focuses on the manufacturing of dewatering and drying equipment for biomass waste, alfalfa, brewery waste, coal and kinds of minerals, etc. * More than 15 years of experience in R&D and manufacturing of drying equipment* 5000 square meters of standardized industrial workshop* Manufacturing capacity of 300 sets of dryers and auxiliary machines* Total online staff more than 200 people

Customer Visit

At present, our products have been recognized by customers in China and all over the world, and successfully exported to Indonesia, South Africa, Vietnam, Thailand, Myanmar, India, Egypt and other countries and regions.

Certifications