Low Price Wood Sawdust Rotating Rotary Drum Kiln Dryer for Wood Chips Coal Slime Mining Slag Feed Granules Magnetic Nickel Sulfate Metal Powder Ceramic Sand

Basic Info

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Transport Package | Standard Wood Package |

| Trademark | XINGGAN |

| Origin | Changzhou, China |

| HS Code | 8419399090 |

| Production Capacity | 40PCS/Year |

Product Description

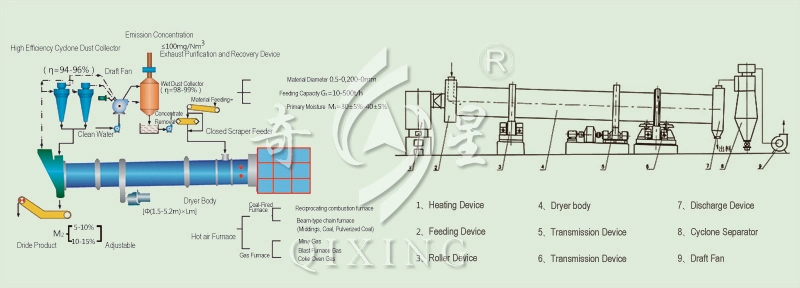

INTRODUCTIONWet material is fed into the inner cylinder by the feeder under the stirring of shoveling plates, uniformly distributed and dispersed in the dryer. After full contact with the hot air (counter flow or current flow) through the barrel, the drying, heat transfer, mass transfer speed up. During the drying process, under the action of the shoveling plates with inclination and hot air, the materials adjustably move to the dryer; after being completed, they are discharged in another star discharge valve.

FEATURES

1. Cylinder dryer has high degree of mechanization and large production capacity.

2. Fluid meets low resistance through the barrel and low power consumption.

3. It has strong adaptability to characteristics of materials.

4. Stable operation and low operating costs, good uniformity of dried product.

APPLICABLE MATERIALS

It is suitable for drying of large particles in chemical, mining, metallurgy and other industries and materials with heavy properties. Such as mine, blast furnace slag, coal, metal powder, phosphate and ammonium sulfate. It is suitable for drying of powder and granular materials which have special requirements, such as HP vesicant, distillers' grains, precipitated calcium carbonate, activated clay, magnetic powder, graphite and dregs of decoction. It is suitable for materials requiring low-temperature and mass continuous drying.

TECHNICAL PARAMETERS

Model /Specification | Production Capacity(t/h) | Rolling Speed(r/min) | Power(kw) | Installation Degree(°) | Discharging Humidity |

Φ1.0x5.0 | 0.5-1.2 | 0.6-6 | 4 | 3-5 | ≤1.5% |

Φ1.2x6-10 | 1.5-3 | 0.6-6 | 5.5 | 3-5 | ≤1.5% |

Φ1.5x12-18 | 3-5.5 | 0.6-6 | 15 | 3-5 | ≤1.5% |

Φ1.8x12-18 | 5-6.5 | 0.6-6 | 18.5 | 3-5 | ≤1.5% |

Φ2.2x12-22 | 7-12 | 0.6-6 | 22 | 3-5 | ≤1.5% |

Φ2.4x15-20 | 9-15 | 0.6-6 | 30 | 3-5 | ≤1.5% |

Φ3.0x25 | 16 | 0.6-6 | 55 | 3-5 | ≤1.5% |

Material / Item | Ore | HP Vesicant | Slag of Blast Furnace | Ammonium Sulphate | Phosphorus Fertilizer | Coal |

Heating Type | Direct heating co-current type | Compound heating | ||||

Processing Capacity(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

Primary Moisture(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

Final Moisture(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

Average Diameter (mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

Bulk Density of Raw Material(kg/m) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

Hot Air Volume(kg/h) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

Inlet Temperature (°C) | 600 | 165 | 500 | 180 | 650 | 570 |

Outlet Temperature (°C) | 42 | 100 | 70 | 80 | 75 | |

Heat Source | Gas | Steam and electric heating | Heavy oil | Coal fuel hot air furnace | Heavy oil | Heavy oil |

Loading Efficiency(%) | 6.3 | 7 | 7.5 | 7.8 | 18 | |

Revolution(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

Gradient(m/m) | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

Dryer Diameter (m) | 2.0 | 1.5 | 2 | 2.3 | Inner cylinder 0.84 Outer cylinder 2 | Inner cylinder 0.95 Outer cylinder 2.4 |

Dryer Length(m) | 20 | 12 | 17 | 15 | 10 | 16 |

Driving Power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

STRUCTURE SCHEMATIC