Automatic High Viscosity Adhesive Grease Silica Gel Silicone Sealant Making Planetary Mixer Machine Planetary Mixer

Basic Info

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Circular Groove |

| Additional Capabilities | Milling, Drying, Granulating, Coating |

| Operating type | Continuous Operating |

| Condition | New |

| Heating Method | Oil Electric |

| Vacuum | -0.098MPa |

| Material | SUS304 or SUS316 |

| Warranty Period | 1year |

| Transport Package | by Sea |

| Specification | 6L TO 2000L |

| Trademark | JCT |

| Origin | Guangzhou |

| HS Code | 847439000 |

| Production Capacity | 1000picecs/Year |

Product Description

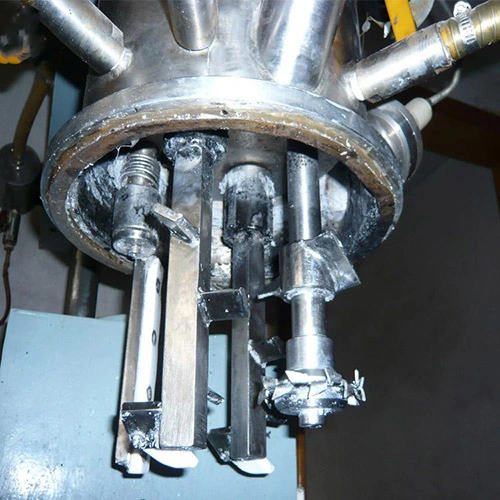

1)Commercial stand type planetary mixers is a kind of highly efficient and versatile mixer with mixing,dispersing, cutting and mixing function;2)There are three different types of planetary mixers in the blender, One of the groups of agitator rotates around the central axis of the kettle body, The other two groups of mixing device with different speed rotation speed, To make the material in the kettle for complex movement,The material is strongly cut and mixed. In the equipment, Vertical shape blade around the axis of the kettle body rotation, on the cylinder wall and bottom material scraped off and Involved in mixing, mixing effect is more ideal.3)in the form of the agitator, according to the material requirements can be designed as a multi- layer blades, frame type, butterfly type, leaf type, etc..4)The sealing performance of the equipment is good, it can be pumped vacuum, the sealing performance of the equipment is good, can be pumped vacuum, can exhaust and eliminate the bubble inside the material .5)The hydraulic lifting device of cylinder, the cylinder can move freely, the operation is very convenient.

Production processPlanetary mixer is a new highly efficient mixing equipment, without dead spots. It is unique and novel in agitation. There are two or three multi-blade stirrer and one or two automatic scraper Agitator runs around the kettle axis, and rotates around its own axis on a different speed at the same time; so that the material in the Kettle crashes intricately, strongly sheared and rubbed. Besides, equipment knife scraped the inside wall of kettle, and bring down the material glued to the wall when rotates around the axis, which greatly enhances the effect .Kettle has special seal structure to pressure and vacuum, so that the exhaust can be well expelled Cylinder jacket can be heated and cooled according to users'needs, Discharging way is pressure fed, covers lift by hydraulic, and cylinder is free to move, which is easy to operate And the impeller and the blade can be rise with the beam out of the cylinder, so it is easy to clean.The equipment is applicable to the process of mix, reaction, disperse, dissolute and quench the multicomponent solid-solid phase, solid-liquid, liquid-liquid materials in the industries of chemical, light industry.food, batteries, pharmaceuticals, building materials, pesticides, It is widely used in the production of ink,paint, adhesives, sealants, filling plastic ointment, paste materials, grease, paint, paste cosmetic, paste food additives and other compounds of high viscous preparation Stirrer is multi-chose in the need of materials requirements, like multi-blade, frame type, butterfly type andt-wheels etc

| model | feeding voluma | planetary motor | high speed motor | Revolution speed | Rotation speed | High speed dispersion speed |

| DLH-6L | 3.6 | 1.5 | 1.5 | 27 | 43 | 0~1000 |

| DLH-20L | 12 | 3 | 3 | 27 | 43 | 0~1000 |

| DLH-60L | 36 | 4 | 4 | 27 | 43 | 0~1000 |

| DLH-100L | 60 | 7.5 | 5.5 | 27 | 43 | 0~1000 |

| DLH-200L | 120 | 15 | 11 | 27 | 43 | 0~1000 |

| DLH-350L | 210 | 18.5 | 18.5 | 27 | 43 | 0~1000 |

| DLH-600L | 360 | 22 | 22 | 27 | 43 | 0~1000 |

| DLH-1000L | 600 | 37 | 30 | 23 | 43 | 0~1000 |

| DLH-1500L | 900 | 45 | 45 | 23 | 43 | 0~1000 |

| DLH-2000L | 1200 | 55 | 45 | 23 | 43 | 0~1000 |

Q : Can you send the formula for the products we want to make ?

A : Our machines can be used for many kinds of product making ,such as Resin , Paint, Adhesive , Cosmetic , Food , Chemicals . There are many kinds of these products , so it's impossible for us to know all the formulas and technologies . We can assist you to find the raw material list you need , and after you place order with us , we can help you to find formula and technology , there will engineers to teach you how to make the product , and the cost will be on your account. Q : Do you have machines in stock ?A : Yes , but just the small-scale machines Machines are different with other products , most of the large-scale machines are designed according to our customers 'requirements different customers have different production requirements , so the technical parameter is different for most machines On the other hands , most of the our machines will cover a large area , so once the machines are finished , we will effect shipment after QC . Q : Can you send the detailed drawings of the machine to us before we place order ?A : We can send you a draft drawing of the machines , and after you place order and pay the deposit , our engineer will design the send you the detailed drawings . Once you confirm without questions , we will put it into production.Q : Why does it take at least 20 days to finish the machine ?A : Once receipt the deposit from you , we will design the drawings and make out the list of the materials and accessories for the production . Once the drawings are finished , our workers will start the production , from welding , polishing , assembling debugging , detection and so on . After finish , they need time to check the machines , if found any possible defect parts , they will return to the production until every part is 100% approved.Q : Can we pay the balance after we receive the machines and test without problem.A : It's unnessary to worry about the quality of our machines , we are confident in that . After the machine is finished . we can install and test the machine for you ( if you can not come to our factory ,we can record a video and send to you ) . Only after you check without problems , we will effect shipment .